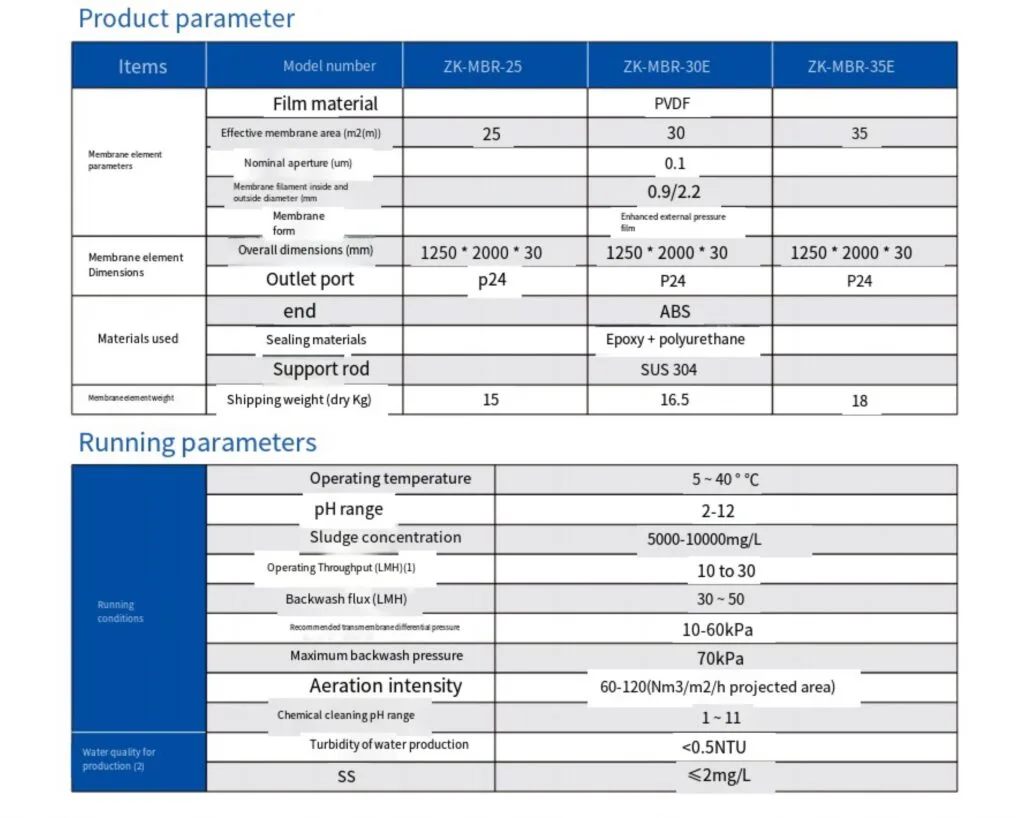

MBR Hollow Membrane

Product Description

Polyvinylidene fluoride, abbreviated as PVDF, mainly refers to the homopolymer of polyvinylidene fluoride or the combination of polyvinylidene fluoride and other small amounts of fluorine-containing ethylene

A copolymer of monomers, which combines the characteristics of fluororesin and general-purpose resin, and has good chemical corrosion resistance, high temperature resistance, oxidation resistance, weather resistance, and radiation resistance

In addition to its performance, it also has special properties such as piezoelectricity, dielectric properties, and thermoelectric properties. It is the second largest production product among fluorinated plastics, with a global annual production capacity of over 53000 tons.

In the chemical structure of PVDF, fluorine carbon bonds form the most stable and strong bond with hydrogen ions due to their short bond properties Therefore, fluorocarbon coatings

It has unique physical and chemical properties, not only strong wear resistance and impact resistance, but also high resistance to fading and purple in extremely harsh and harsh environments

External line performance.

Due to its excellent physical and chemical properties, PVDF has a significant market share in the preparation of ultrafiltration and microfiltration

Features

Application Scenarios

Polyvinylidene fluoride, abbreviated as PVDF, mainly refers to the homopolymer of polyvinylidene fluoride or the combination of polyvinylidene fluoride and other small amounts of fluorine-containing ethylene

A copolymer of monomers, which combines the characteristics of fluororesin and general-purpose resin, and has good chemical corrosion resistance, high temperature resistance, oxidation resistance, weather resistance, and radiation resistance

In addition to its performance, it also has special properties such as piezoelectricity, dielectric properties, and thermoelectric properties. It is the second largest production product among fluorinated plastics, with a global annual production capacity of over 53000 tons.

In the chemical structure of PVDF, fluorine carbon bonds form the most stable and strong bond with hydrogen ions due to their short bond properties Therefore, fluorocarbon coatings

It has unique physical and chemical properties, not only strong wear resistance and impact resistance, but also high resistance to fading and purple in extremely harsh and harsh environments

External line performance.

Due to its excellent physical and chemical properties, PVDF has a significant market share in the preparation of ultrafiltration and microfiltration membranes

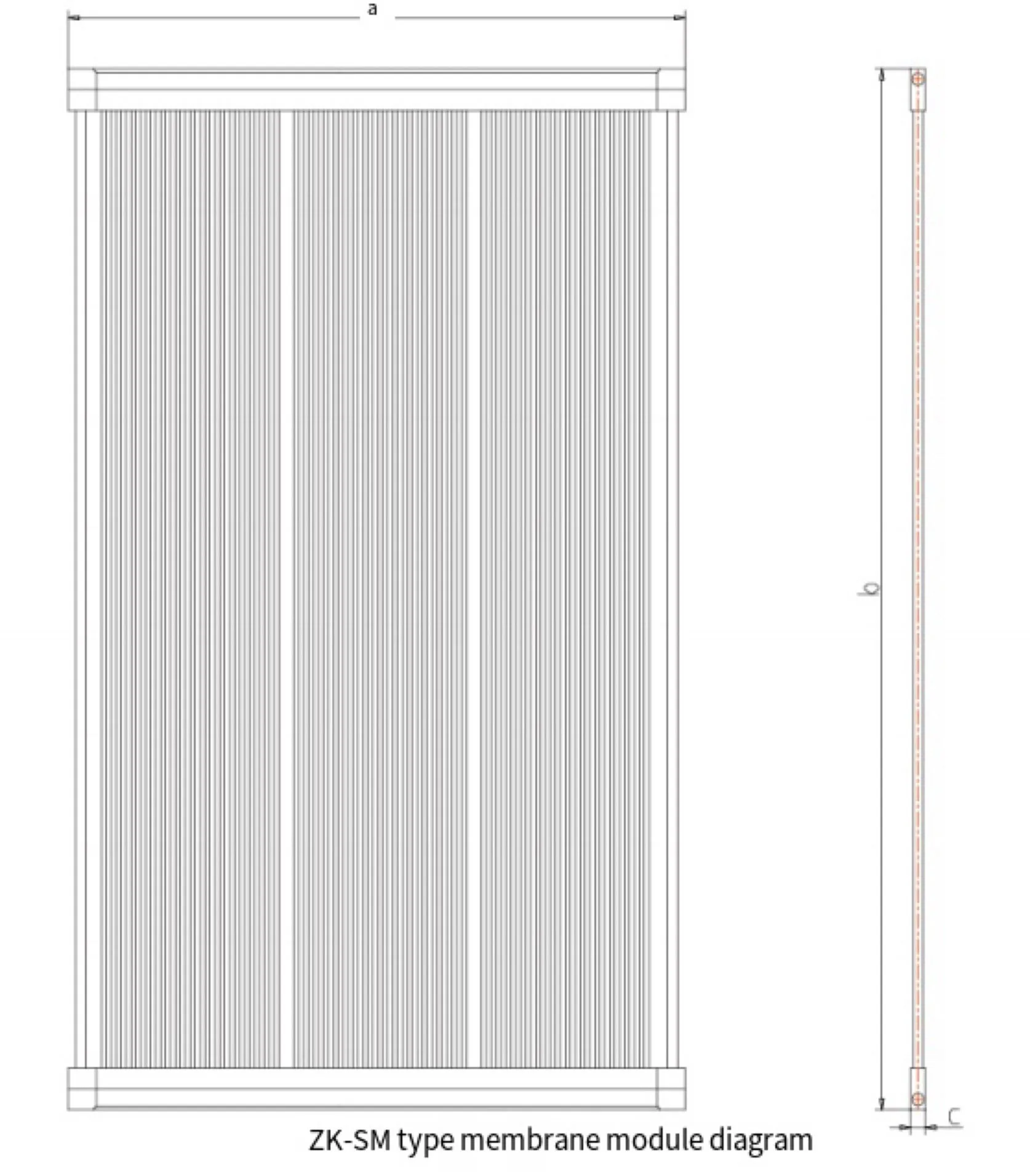

Detailed images

Product advantages and features

Low energy consumption and high efficiency

Low pressure high flux, high pressure stable operation

Maximum increase in operating flux by 40%, with less demand for chemical agents

Long cleaning cycle

Reduce pollution rate by 75% and have strong resistance to attenuation

Resistance duration increased by 200%, easy to clean and recover

Long service life

High mechanical strength, continuous threading

Permanently hydrophilic, slow flux decay

Safe and reliable water production

Uniform pore size and high porosity

High peel strength, no peeling

Low energy consumption, high efficiency

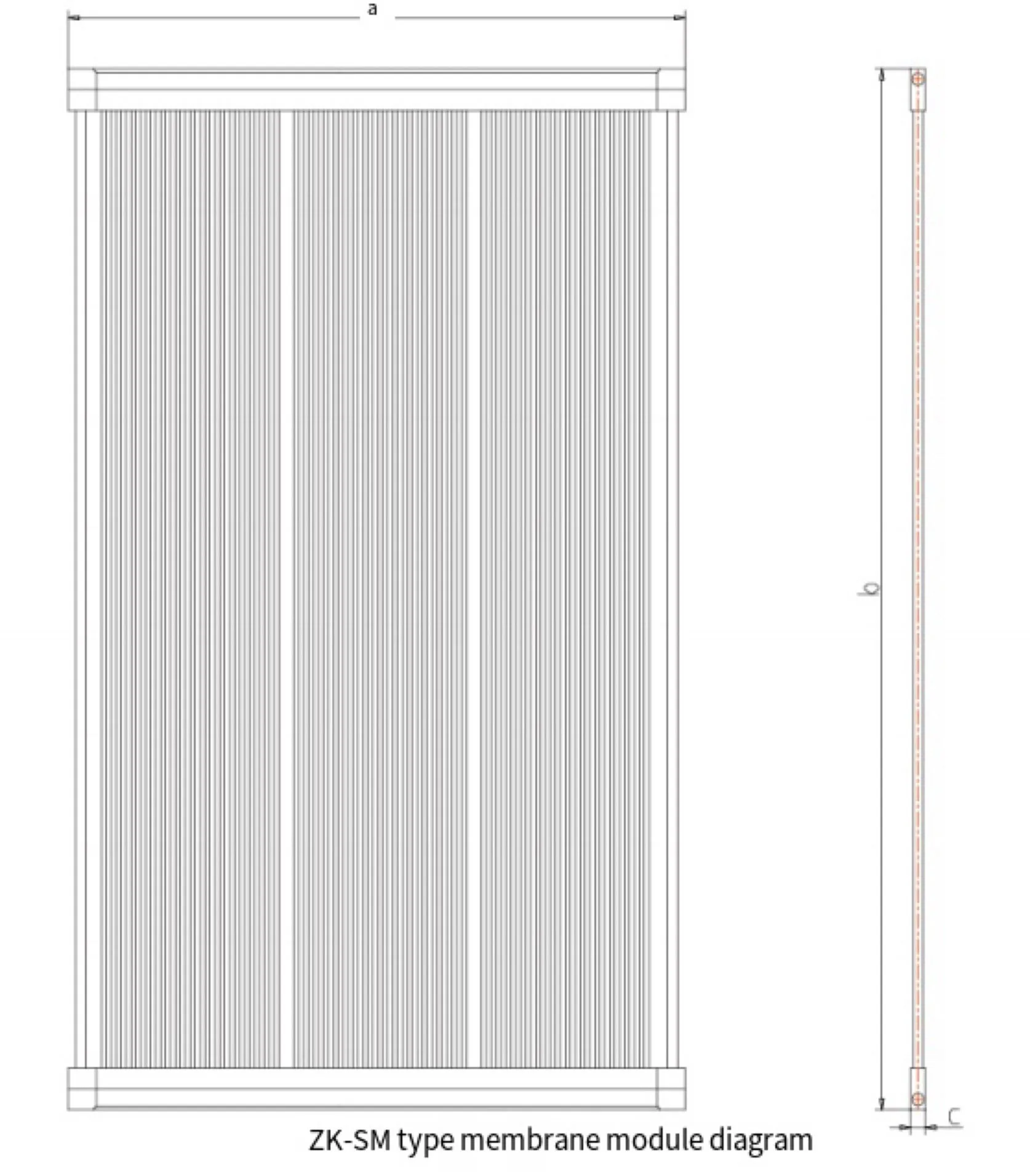

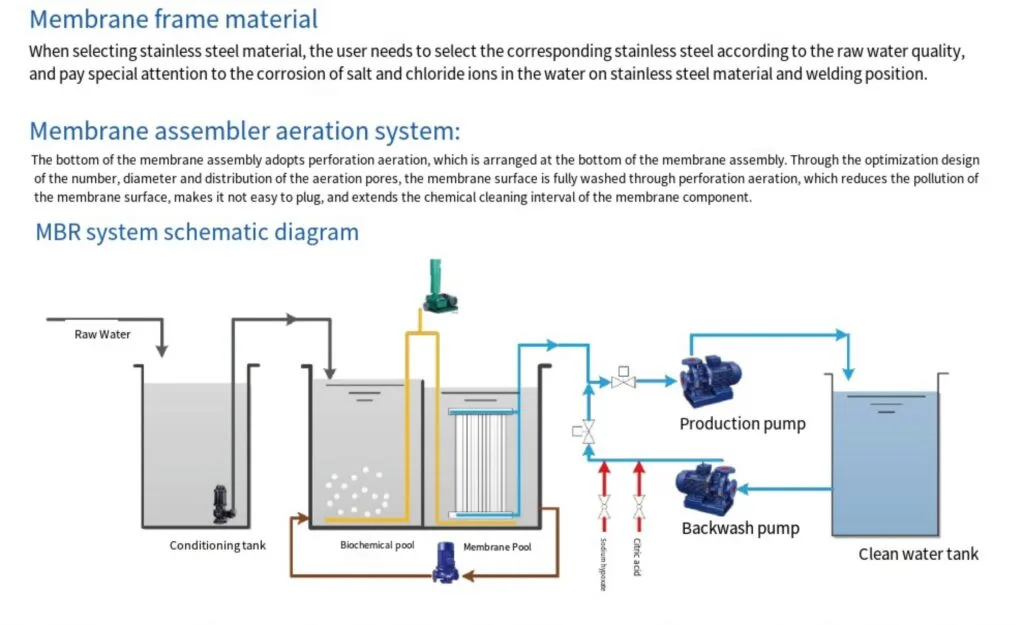

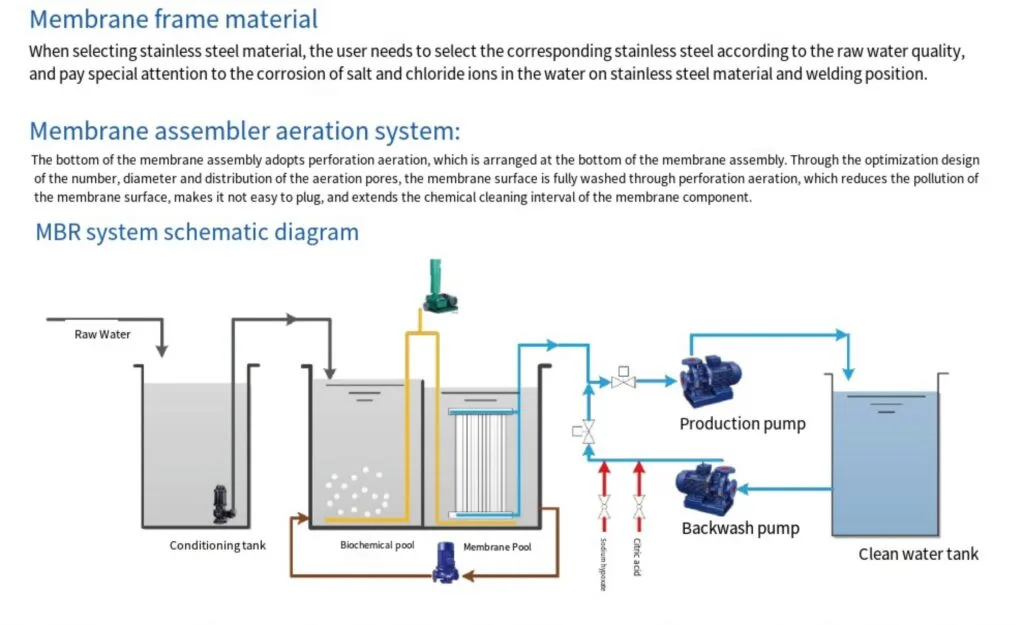

Membrane frame material

When selecting stainless steel materials for membrane module support, water production, and aeration main pipes, users need to choose the corresponding stainless steel according to the quality of the raw water, especially considering the water quality

Corrosion of stainless steel materials and welding positions by salt and chloride ions.

Membrane module aeration system:

The bottom of the membrane module adopts perforated aeration, which is arranged at the bottom of the membrane module. By optimizing the number, diameter, and distribution of aeration holes, perforated aeration is achieved

Thoroughly flush the membrane surface to reduce surface contamination, making it less prone to clogging and extending the chemical cleaning interval of membrane components.

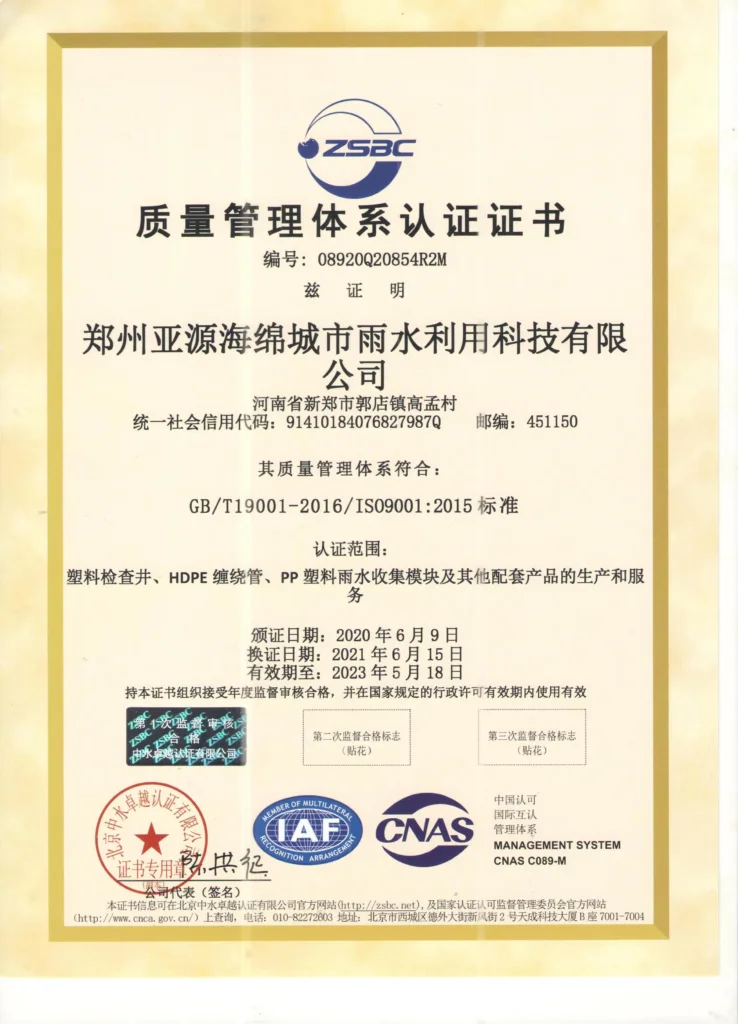

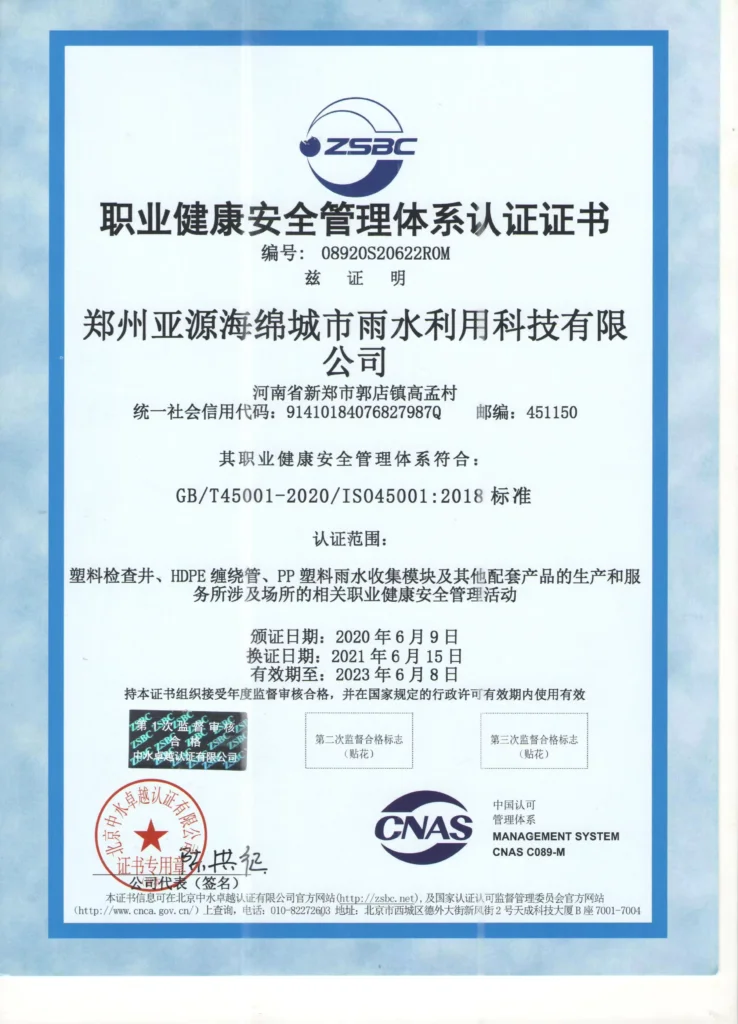

Related Certificate

FAQ

We are available 7/24.Please leave your Email or click onlinechat to let us serve you.

Yes.Please feel free to contact us.

It depends on the order quantity and the season you place the order. Usually we can ship within 7-15 days for small quantity,and about 30 days for large quantity.

T/T,Western Union,MoneyGram,and Paypal.This is negotiable.

It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).Please confirm with us before placing orders.

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

We provide free technical guidance and installation assistance, and if necessary, we will send technicians to the site for guidance

Yes, we produce all products related to Sponge City. For specific information, please consult our online customer service

Yes, we provide free deep optimized construction drawings